| |

Project Overview | Project Code: ED 16 |

|---|---|

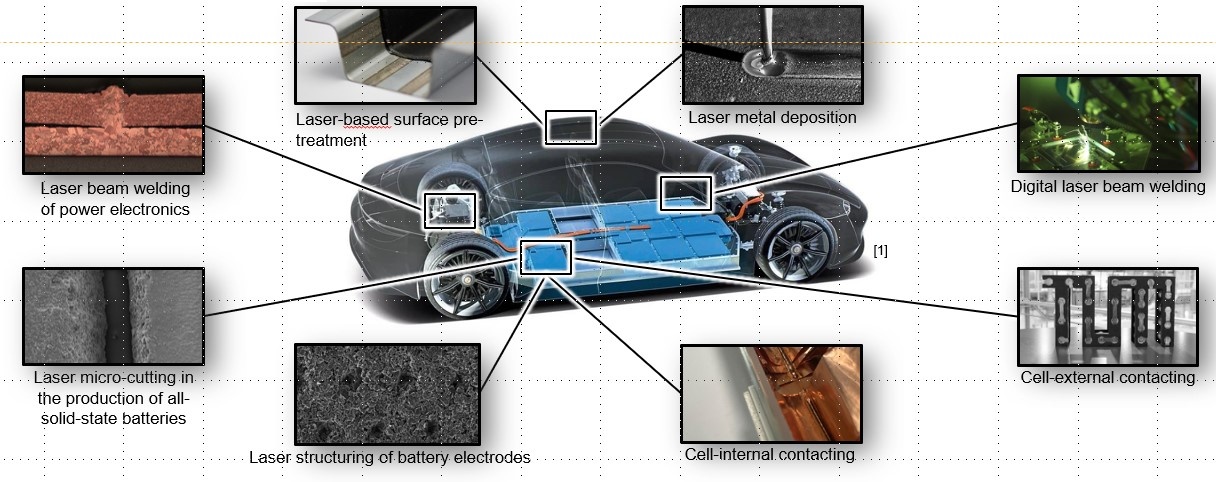

| Project name: | Laser-Based Manufacturing Process in Hydrogen and E-Mobility |

| TUM Department: | ED - Mechanical Engineering |

| TUM Chair / Institute: | Institute for Machine Tools and Industrial Management (iwb) |

| Research area: | production technology |

| Student background: | Aerospace / GeodesyComputer ScienceComputer Science/ InformaticsElectrical EngineeringMechanical EngineeringPhysics |

| Further disciplines: | |

Planned project location: | Boltzmannstraße 15, 85748 Garching bei München |

Project Supervisor - Contact Details | |

|---|---|

| Title: | M.Sc. |

| Given name: | Pawel |

| Family name: | Garkusha |

| E-mail: | Pawel.Garkusha@iwb.tum.de |

| Phone: | +49 1578 4039262 |

Additional Project Supervisor - Contact Details | |

|---|---|

| Title: | |

| Given name: | |

| Family name: | |

| E-mail: | |

| Phone: |

Additional Project Supervisor - Contact Details | |

|---|---|

| Title: | |

| Given name: | |

| Family name: | |

| E-mail: | |

| Phone: |

Project Description | |

|---|---|

| Project description: | Initial situation |

| Working hours per week planned: | 35 |

Prerequisites | |

|---|---|

Required study level minimum (at time of TUM PREP project start): | 3 years of bachelor studies completed |

| Subject related: | - Basic programming skills preferably (MatLab or Python) |

| Other: | - Interest in systems theory and control engineering |